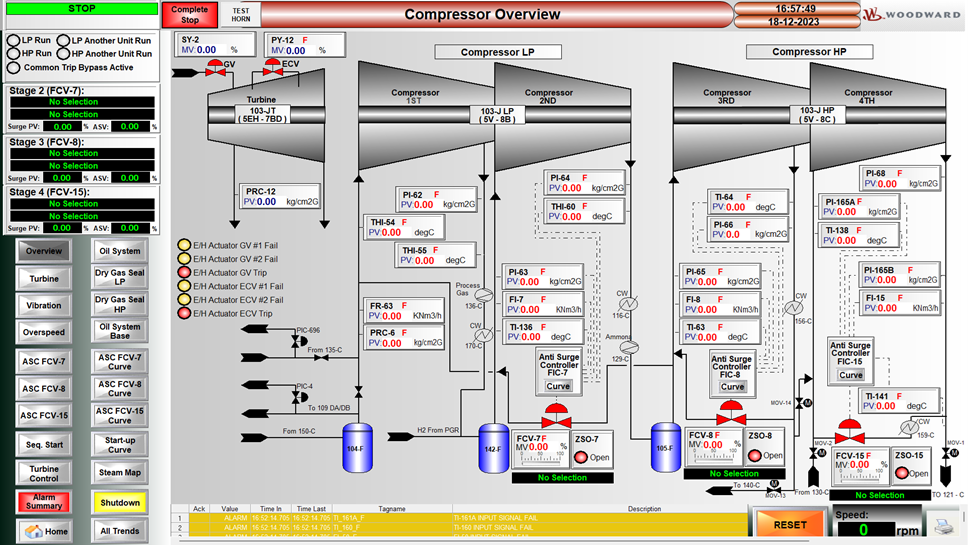

Krishak Bharati Cooperative Limited (KRIBHCO) is a premier National level Cooperative Society of India engaged in fertilizer production and distribution and is registered under Multi State Cooperative Societies (MSCS) Act, 2002. KRIBHCO was founded in April 1980, to produce and distribute high-quality agricultural inputs, mainly chemical fertilizers, through cooperatives and institutional agencies. The paid-up share capital of KRIBHCO has been contributed by 9478 cooperative societies from all over the country. KRIBHCO believes in keeping with its cooperative philosophy and legacy while incorporating technology to better serve the nation. KRIBHCO’s production facility is located at Hazira, Gujarat and its wholly-owned subsidiary KRIBHCO Fertilizers Limited (KFL) production facility is located at Shahjahanpur, Uttar Pradesh. Oman India Fertiliser Company S.O.A.C. (OMIFCO), a Joint Venture of KRIBHCO has its production facility in SUR, Oman. In addition to production of fertilizers, Society is also engaged in trading and distribution of bulk fertilizers like DAP, NPK, MOP etc. The product basket of KRIBHCO comprises of Urea, DAP, NPK, MOP, SSP, Zinc Sulphate, Bio-Fertilizers, Certified Seed, Compost, Hybrid Seeds, BT Cotton etc. KRIBHCO distributes these products through its channel partners both in cooperatives and private retail. It also supplies products through and its own outlets, commonly known as KBSK’s. To achieve zero effluent from the plant, the following inbuilt facilities have been provided: Process condensate stripper to strip off dissolved gases from process condensate with steam. After stripping the condensate is sent to DM plant for further treatment to convert it to the De-mineralized Water. Turbine condensate is sent to DM plant for polishing and used as boiler feed water. Boiler blow down is used as cooling tower make up The Process Steps are: 1.Primary & Secondary Reforming: In Primary Reformer, feed Natural Gas reacts with Steam. Air is injected in Secondary Reformer to provide source of Nitrogen for Ammonia synthesis. 2.CO Shift Conversion: Carbon monoxide produced is converted to Carbon dioxide by reaction with steam. 3.CO2 Removal: Carbon dioxide removed and recovered by absorption in GV solution. 4.Methanation 5.Ammonia Synthesis and Ammonia Separation 6.Purge Gas Recovery Our Project was for the Ammonia Plant 1 & 2 of KRIBHCO where we upgraded the SCADA system to Proficy iFIX v2022 with Historian and provided new features such as Data logging, SQL server for alarm logs, Reports.

LOADING...

No references available